Supravac – Machines for vacuum forming.

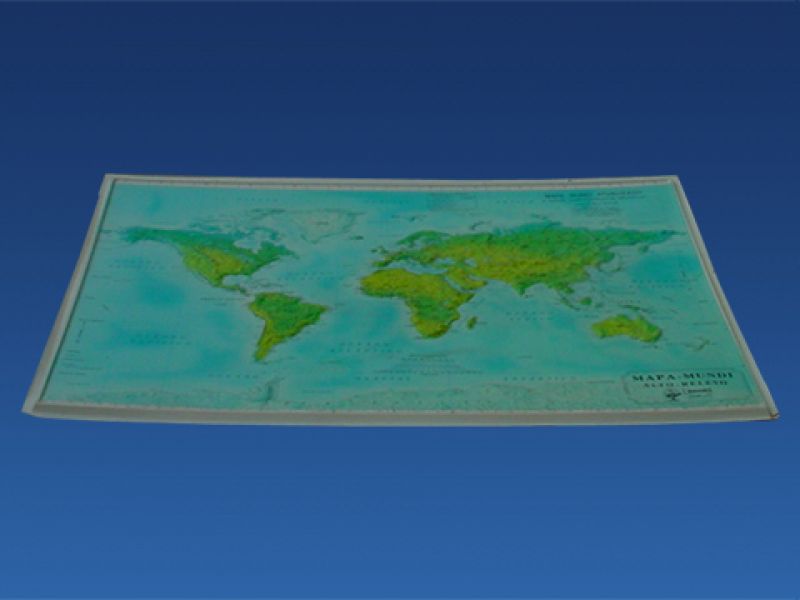

Supravac is an automatic single station Vacuum Forming machine. It has an upper oven, which makes it flexible and cost-effective, especially when thermoforming with a variety of molds in a single production shift.

SUPRAVAC molds various types of thermoplastics, mainly PS and ABS. The equipment is suitable for thermoforming up to 6 mm thick, depending on the material. It can be assembled in sizes from 800mm x 600mm up to 5000mm x 3000mm molding area.

- - LAKATOS 4.0

Connectivity, integration and remote maintenance for your shop floor. - - IN ACCORDANCE WITH SAFETY STANDARS

Vídeos

General Features

- Automatic cycle - unless material is loaded and removed.

- Operates with male and female molds.

- Ovens with resistance of standardized infrared radiation, easy maintenance. Ovens built in stainless steel suitable for thermal expansion and designed to save energy.

- Heating distribution through resistance zones. The number of zones varies according to machine size. Temperature control for each zone (PID auto tunning).

- Pre-blow or pre-insufflator.

- Equipped with plug assist (Plug).

- Possibility to equip with sliding parts in the plug assist (Servomotor – optional).

- Vacuum system equipped with different stages of pressure x flow. Equipped with high pressure vacuum pumps (oil pump) and flow associated with tanks.

- Compressed air to remove thermoformed part from the mold.

- “Teach” function keys to adjust mold and plug assist height.

- Centrifugal high-flow blowers with low noise to cool the molded plastic.

- High performance and large capacity PLC. It can control heating zones, times, alarms, various setups, parts counters and many other parameters. It offers options for over 100 moldes.

- Easy to understand Human Machine interface. MMI size varies according to machine size.

- Machine brings safety equipment for the operator, such as light curtains.

- First-class components.

- Machine project is designed with parameters that allow easy customization to meet each customer´s needs.

- Infrared temperature sensor to control heating cycle by plastic temperature.

- Water spray blowers - reduce cooling time, giving faster cycles, increasing productivity.

- Mold temperature control.

- Compressed air spots in the plug.

- Quick molding change with transfer spheres on the mold table.

- Sliding frames to speed up sheet size change.

Lakatos provides operation and maintenance manual, electric and pneumatic plants and list of components for easy maintenance. 1-year guarantee on all parts and components. 1-year guarantee on all parts and components.

© 2025 ELETRO FORMING EQUIPAMENTOS PARA EMBALAGENS LTDA | CNPJ: 43.357.193/0001-45