Lakatos

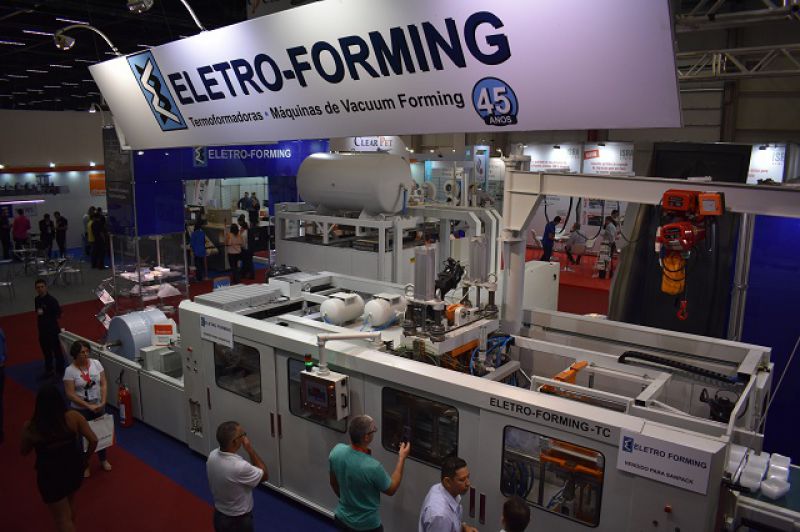

A reference in the thermoforming machine manufacturing market for over 50 years.

Headquartered in the municipality of Itapecerica da Serra (São Paulo), Lakatos operates a 6,000 m² production facility. The site includes departments for machining, boilerwork, metalworking, assembly, painting, metrology, and also a parts inventory for prompt service.

The company has a highly skilled team dedicated to project development and the integration of the latest technologies. Its production line features CNC machining centers capable of manufacturing a wide range of complex parts and molds.

Lakatos' Engineering and Production departments are equipped with state-of-the-art software (CAE, 3D CAD, EPLAN, and CAM). An ERP system integrates the company’s various departments.

E-mail: manuel@jmmuntadas.net

OUR COMPANY TIMELINE

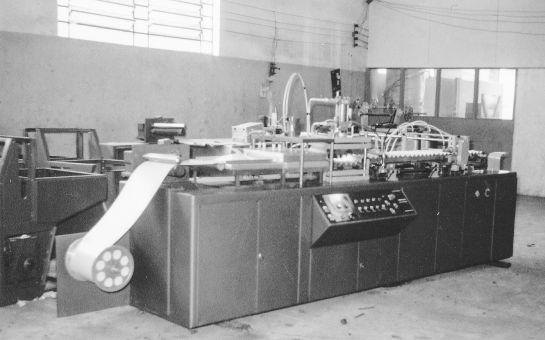

The company is founded and starts its activities. The following year begins the production of one of the largest vacuum-forming machines in Brazil at the time, size: 2m x 1m.

First automatic machine for pharmaceutical blister made in Brazil, Pharmapack.

Launched automatic molding and cutting machine.

Construction of the first Rotomolding machine.

Manufacture of packaging machines.

Opening of our headquarters in Embu.

The manufacture of rotary machines RV-2 began.

Started the production of current thermoformers with cutting TC 600mm X 400mm.

We acquired our first CNC milling machine, followed by others.

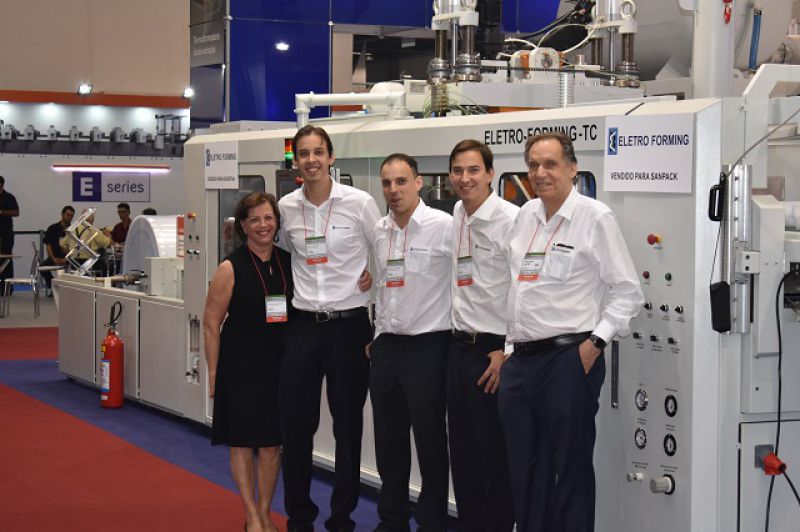

Entry of the second generation of the Lakatos family into the company's corporate structure.

Launched the SUPRAVAC-2 that in addition to the traditional parts molds PE and PP.

Exports already represent 30% of our revenues.

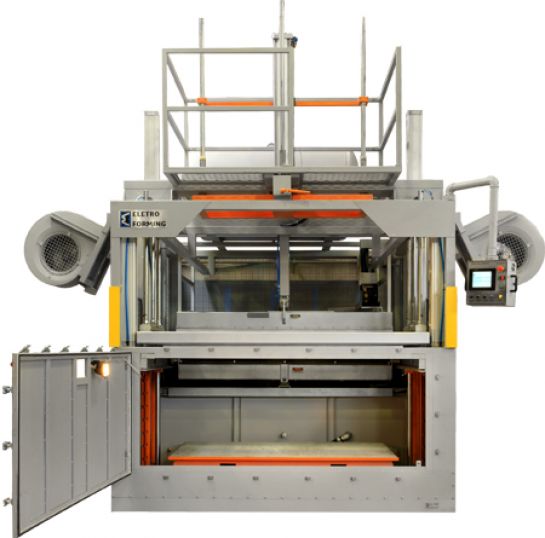

The second generation of the TC 600 X 400 thermoforming machine was launched with the servomotors chain, with 4 columns, with a stacker that counts and removes parts from the machine.

Beginning of the thermoformer manufacturing process with all movements driven by servomotors and with press drive system with patent deposited.

Started to Manufacturing of machinery line TA for the production of flakes and pots, with ferramenta male/female tool. The press and patent system of double eccentric. This system has several advantages compared to conventional equipment.

Starting production of the 3rd generation of TC - 700 X 500 with all movements driven by servomotor: lower press, upper press, material advance, stacker and plug. We also started to offer the complete online packaging system, provided by partner companies.

We have consolidated our tooling by expanding production capacity for up to 20 continuous thermoforming molds per year.

Magnification of TC line sizes with TC-1, TC-2 and TC-3 models. The TC-1 can meet up to a blister production or allow the start of a thermoforming company with a competitive equipment.

Production of TCM lines started with 2 or 3 press stations plus stacker.

© 2025 ELETRO FORMING EQUIPAMENTOS PARA EMBALAGENS LTDA | CNPJ: 43.357.193/0001-45