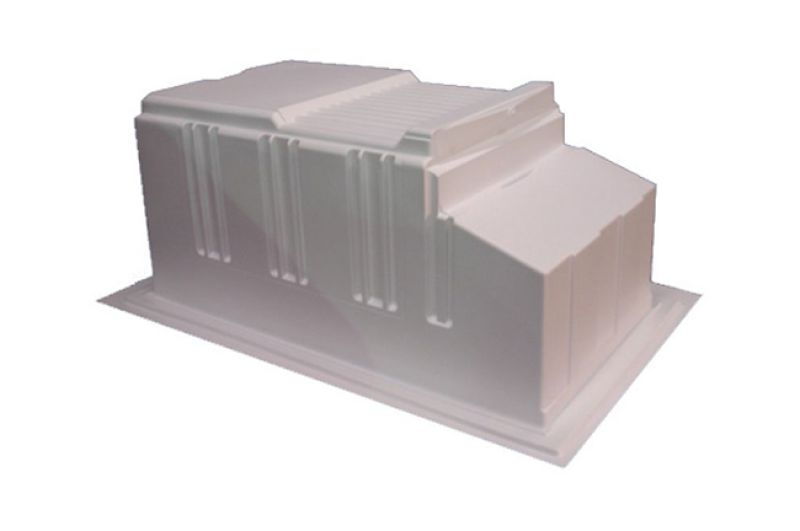

Application: Refrigerator parts application

The refrigeratior parts equipment industry is one of those that most uses thermoforming process. Home refrigerators have inner thermoformed cabinets, thermoformed door liners and thermoformed covers in large scale.

Commercial refrigerators also have many thermoformed parts, such as cabinets, freezer parts, blinds, cabinets lateral and careenage. The products described above are usually produced by HIPSA and/or ABS sheets with 1 to 6 mm thick.

Lakatos offers single station machines for small scale production, as well as rotary machines RV-2 and custom equipment for continuous lines that mold and cut automatically.

Our machines add the following technologies: Automatic feeding the use of pre-blow in the male molds, mold temperature control and division of warming zone by element.

Briefly understand the productivity of our machines for some parts:

Internal Cabinets

Machine: Supravac-2

Plastic: HIPS 3,5mm

Cavities in mold: 1

Production capacity: 15 pieces / hour

Machine: RV-2

Production capacity: 27 pieces / hour

Door liners

Machine: Supravac-2

Plastic: HIPS 1,3mm

Cavities in mold: 1

Production capacity: 35 pieces / hour

Machine: RV-2

Production capacity: 80 pieces / hour

Learn more about each Lakatos machine regarding this application: