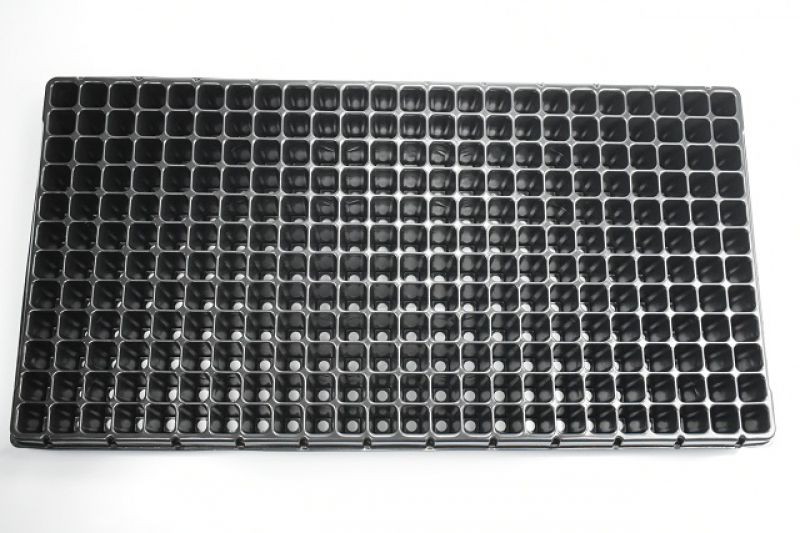

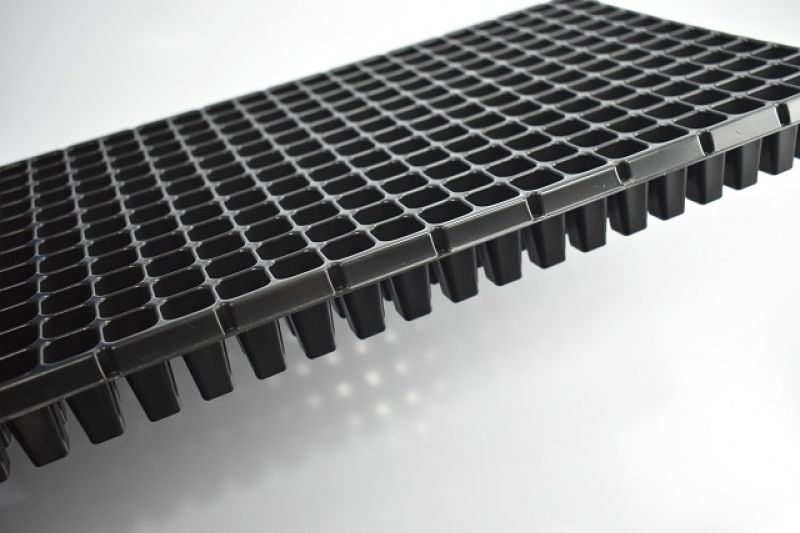

Application: Planting tray application

Lakatos has machines capable of manufacturing seedling trays or pot holders in different sizes. They include 128 and 200 cell trays and 15 cavities pot holders. These products are made of PS, PP or PET, with thickness from 0,5 to 1,5 mm. The recommended machines for manufacturing these items are the TC and the TCM in case of pieces with holes.

The TC line molds and cuts on the same station, stacks and takes the packing pile counted on a conveyor belt, while the TCM line molds, punches, cuts, stacks and also takes the packing piles counted on a conveyor belt.

The manufacture of these trays requires the following technologies offered by Lakatos machines:

- Steel-rule knife cutting - less cost of the mold compared with punched cut machines.

- Pressure forming that guarantees highspeed and more precise definition in the molded parts (mandatory for PP parts).

- Floating knife to ensure good centering of cut and uniform flaps.

Briefly understand the productivity of our machines for some parts:

Machine: TC-2 or TCM 700 mm x 500 mm.

Production capacity: 25 cycles per minute in PS 0,60 mm.

Planting tray of 15 cells: 4 cavities mold and production capacity of 6.000 trays per hour.

Pot tray of 15 cavities: 4 cavities molds and production capacity of 7.000 cup holders per hour.

Tray of 128 cells: 1 cavity mold and production capacity of 1.3000 trays per hour.

Tray of 200 cells: 1 cavity mold and production capacity of 1.500 trays per hour.

Learn more about each Lakatos machine regarding this application: