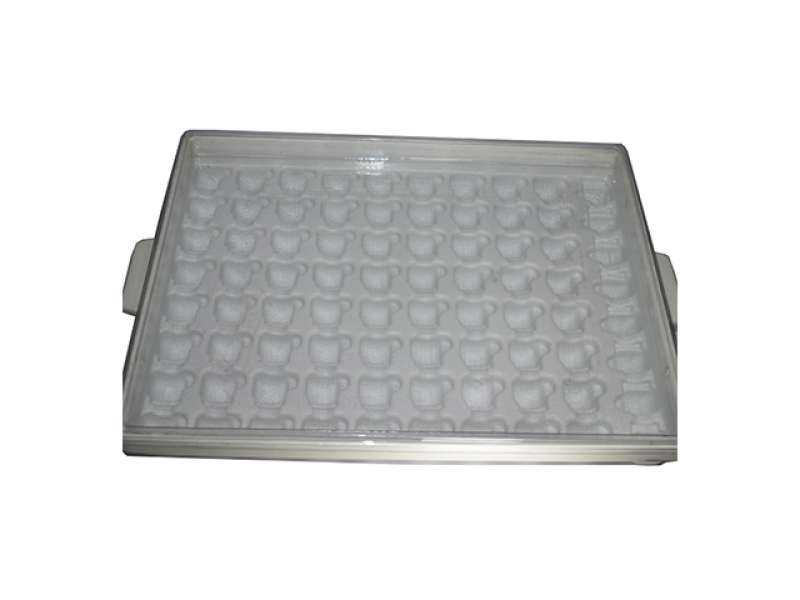

Application: Pallets application

Lakatos Supravac-2 and RV-2 are capable of manufacturing plastic pallets from PP and HDPE, from 3 to 10 mm thick. The first machine has single and double oven station, being able to produce pallets in both PP and HDPE. Supravac 2 has a sag support system during the heating process, which ends in higher quality for the final part. RV-2 has a double station and double oven, has a rotating frame and has a higher productive capacity for HDPE pallets. The thermoformed pallets have some advantages over injected or wood ones, such as: thinner walls, less internal tension, lower weight and low tooling costs. Molding these parts requires the following technologies offered by Lakatos machines: - Double oven - Auto feeding - PID control with autotunning in both ovens - Pre-blow and plug assist Briefly understand the productivity of our machines for some parts: Pallet

RV-2: Máquina para Vacuum Forming com duas estações e forno duplo

Supravac-2: Termoformadora monoestação de forno duplo