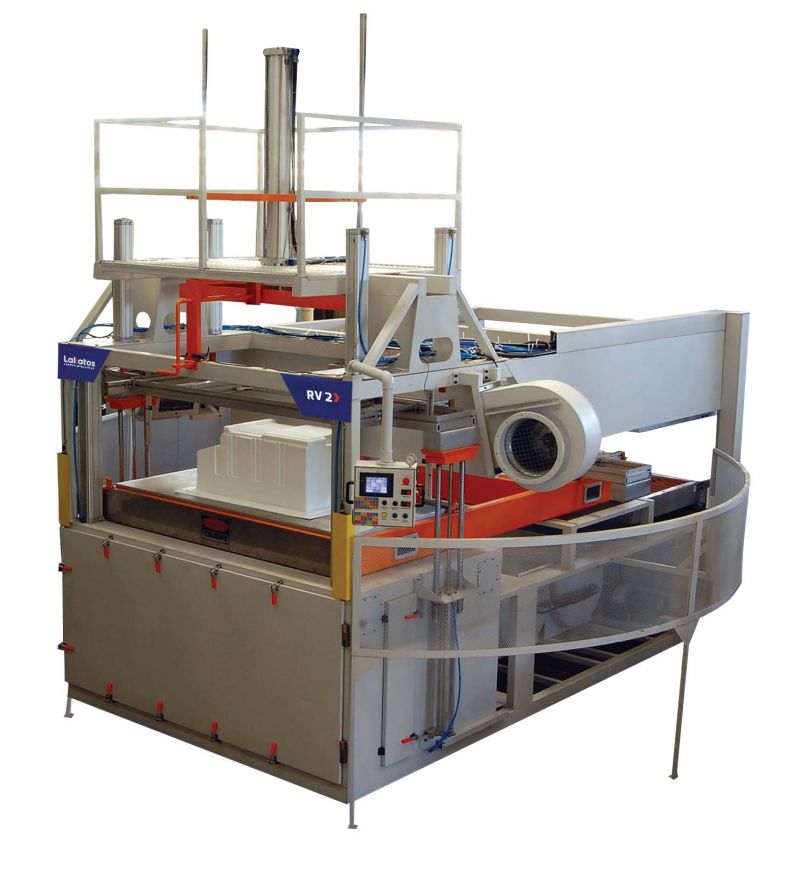

RV-2: Vacuum Forming Machine with Two Stations and Double Oven

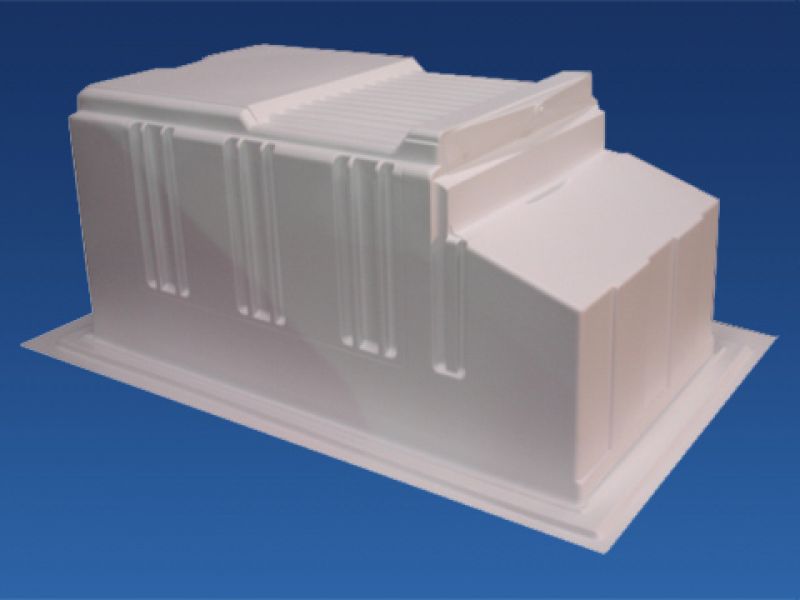

RV-2 is an automatic machine that produces thermoformed parts with thickness above 1mm. This machine is two station carousel type, that is, a rotary vacuum forming machine in which both frames rotate. While one sheet is heated, another one is being molded and cooled. This system gives the machine far greater productivity when compared to single-station ones. RV-2 has two ovens, making the molding of various materials possible.

- Lakatos 4.0

Connectivity, integrationand remote maintenancefor your shop floor.

- IN ACCORDANCE WITHSAFETY STANDARDS.

Vídeos

crypted

General Features

- Automatic cycle - unless material is loading and unloading.

- Heats the plastic sheet from both sides by a double oven. Thick materials are heated in less time and with less difference of temperature between the two sides. As it is a rotary-type machine, the ovens are always in use, which increases productivity and saves energy.

- Molds various materials (ABS, PS, PVC, PMMA) with 1 to 10mm thickness.

- Operates with male and female molds.

- Ovens are made with infrared irradiation elements, easy-to-maintain standardized. The ovens are built with stainless steel, able to absorb thermal dilations and designed to save energy.

- Heating distribution by using several heating zones in the oven. The number of zones varies according to machine size. PID individual temperature control for each heating zone.

- Pre blow.

- Plug assist equipped (Plug).

- Possibility to be equipped with sliding parts in the mold and in the plug assist.

- Vacuum system with 2 molding flows. High pressure and flow vacuum pumps with large tanks.

- Compressed air to remove thermoformed part from the mold.

- “Teach” function keys and ajustable mold and plug assist height.

- Rotation movement of frames by servo-motor and clutch.

- Centrifugal high-flow fans to cool the thermoformed plastic.

- High performance and large capacity PLC. It can control: heating zones, times, alarms, various setups, parts counters and many other parameters. It offers options for over 100 moldes.

- Easy to understand man machine interface. MMI (size varies according to machine size).

- First-class components. Machine is designed with parameters that allow easy customization to meet each customer´s needs.

In addition to choosing the size of the molding area, it is alsopossible to equip RV-2 with the following optional items:

- Infrared temperature sensor to control heating cycle by plastic temperature.

- Water spray - reduce cooling time, giving faster cycles, increasing productivity.

- Mold temperature control.

- Compressed air spots in the plug.

- Quick molding change with transfer spheres on the mold table.

- Sliding frames to speed up sheet size change.

Lakatos provides operation and maintenance manual, electric and pneumatic plants and list of components for easy maintenance. 1-year guarantee on all parts and components.

© 2025 ELETRO FORMING EQUIPAMENTOS PARA EMBALAGENS LTDA | CNPJ: 43.357.193/0001-45